| ASTM A179 |

| ASTM A192 |

| ASTM A209: Gr.T1, Gr. T1a, Gr. T1b |

| ASTM A210:Gr.A1, Gr.C |

| ASTM A106: Gr.A, Gr.B, Gr.C |

| DIN 17175: ST35.8, ST45.8, 15Mo3, 13CrMo44 |

| EN 10216-2: P235GH, P265GH, 16Mo3, 10CrMo5-5, 13CrMo4-5 |

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A178:Gr.A, Gr.C |

| ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 |

| ASTM A333: Gr.1, Gr.3, Gr.4, Gr.6, Gr.7, Gr.8, Gr.9.Gr.10, Gr.11 |

| ASTM A312/A312M:304, 304L, 310/S, 310H, 316, 316L, 321, 321H etc... |

| ASTM A269/A269M:304, 304L, 310/S, 310H, 316, 316L, 321, 321H etc... |

| EN 10216-5:1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 |

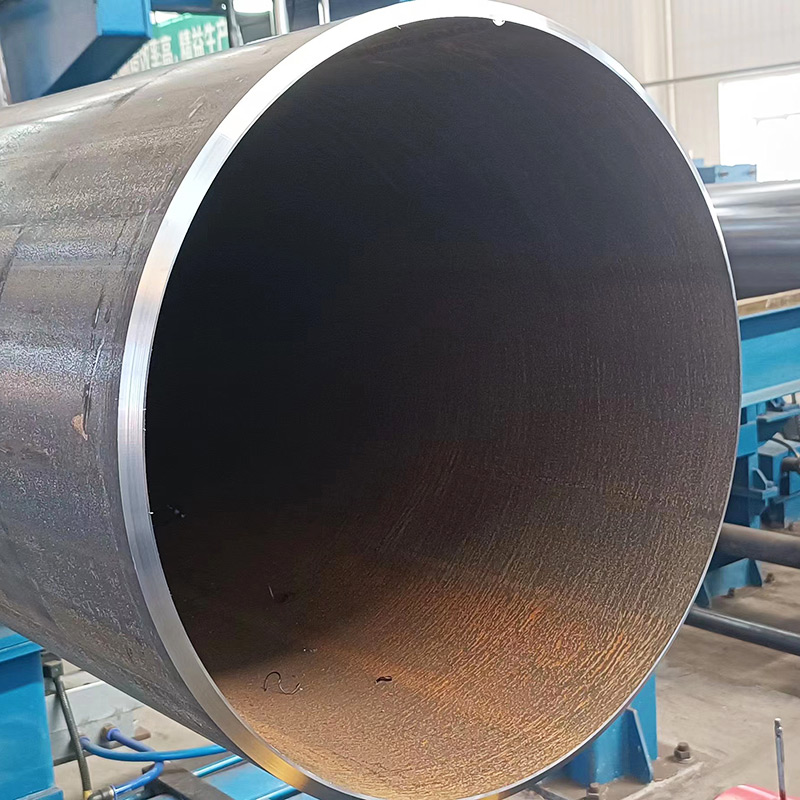

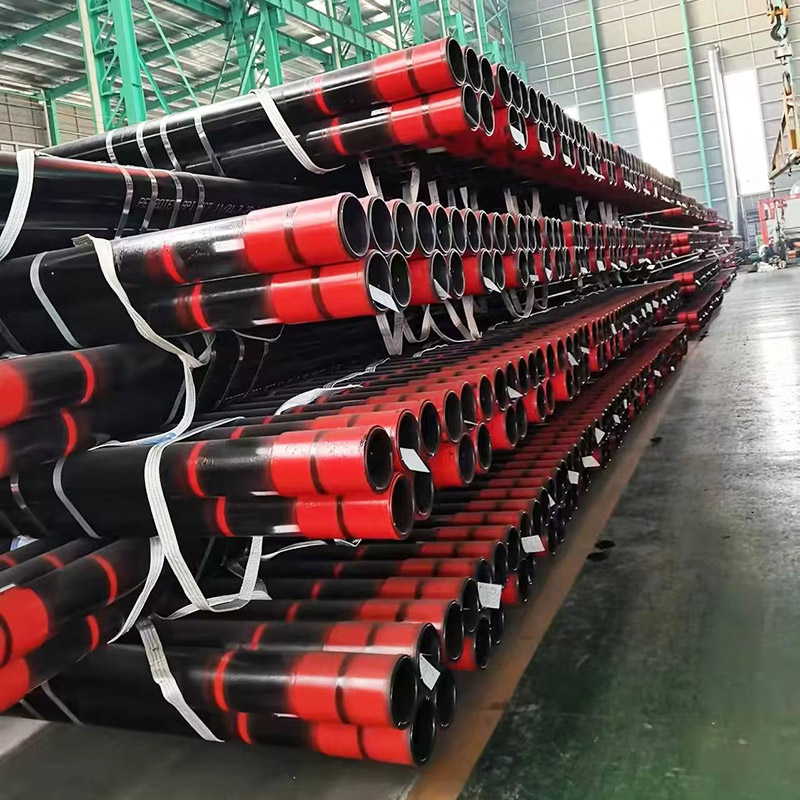

Steel pipes serve as the backbone of modern industrial and civil engineering, supporting a wide array of applications that contribute to the development of societies and economies worldwide. The steel pipes and fittings we Womic Steel produced widely used for petroleum, gas, fuel & water pipeline, offshore /onshore, sea port construction projects & building, dredging, structural Steel, piling and bridge construction projects, also precision steel tubes for conveyor roller production, ect... Boiler Tubes Standard Grades: ASME SA-179M, ASME SA-106, ASTM A178, ASME SA-192M, EN10216-1, JIS G3461, ASME SA-213M, DIN17175, DIN1629. Delivery Condition: Annealed, normalized, tempered. surface oiled, black painted, shot blasted, hot dipped galvanized.

Steel pipes serve as the backbone of modern industrial and civil engineering, supporting a wide array of applications that contribute to the development of societies and economies worldwide. The steel pipes and fittings we Womic Steel produced widely used for petroleum, gas, fuel & water pipeline, offshore /onshore, sea port construction projects & building, dredging, structural Steel, piling and bridge construction projects, also precision steel tubes for conveyor roller production, ect... Boiler Tubes Standard Grades: ASME SA-179M, ASME SA-106, ASTM A178, ASME SA-192M, EN10216-1, JIS G3461, ASME SA-213M, DIN17175, DIN1629. Delivery Condition: Annealed, normalized, tempered. surface oiled, black painted, shot blasted, hot dipped galvanized. | ASME SA-179M: | Seamless Cold Drawn Low Carbon Steel Heat Exchanger and Condenser Tubes. |

| ASME SA-106: | Carbon Steel Pipe For High Temperature Service. |

| ASTM A178: | Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater Tubes. |

| ASME SA-192M: | Seamless Carbon Steel Boiler Tubes for High Pressure Devices. |

| ASME SA-210M: | Seamless Medium Carbon Steel Boiler and Superheater Tubes. |

| EN10216-1/2: | Seamless non-alloy steel tubes for pressure purposes with specified room temperature properties. |

| JIS G3454: | Carbon steel pipes for pressure service at an approximate maximum temperature of 350 Degrees Celsius |

| JIS G3461: | Carbon Steel Tubes for Boiler and Heat Exchanger. |

| GB 5310: | Seamless steel tubes and pipes for high pressure boiler. |

| ASME SA-335M: | Seamless ferritic and austenitic alloy steel boiler, superheater and heat-exchanger tube. |

| ASME SA-213M: | Alloy Steel Tubes for boilers, superheaters and heat exchangers. |

| DIN 17175: | Seamless Steel Tubes for Boiler Industry, heat-resisting seamless steel tube, used for the pipelines of boiler industry. |

| DIN 1629: | Overheated boilers, manufacturing pipeline, vessel, equipment, pipe fittings, and as heat exchangers via austenitic pipes. |