| Norminal Outside Diameter (mm) | Actual Outside Diameter (mm) | Outside Diameter(mm) | Ovality Max. | Norminal preferred Wall Thickness | Norminal alternative Wall Thickness | |

| Max. | Min. | (mm) | (mm) | |||

| 101 | 101.6 | 101.8 | 101.4 | 0.4 | 3 | 3.5 |

| 108 | 108 | 108.2 | 107.8 | 0.4 | 3.8 | 4.5 |

| 127 | 127 | 127.2 | 126.8 | 0.4 | 3.8 | 4.5 / 6 |

| 133 | 133.1 | 133.3 | 132.9 | 0.4 | 4 | 6 |

| 152 | 152.4 | 152.6 | 152.2 | 0.4 | 54 | 6 |

| 159 | 158.8 | 159.1 | 158.6 | 0.5 | 4 | 6 |

| 165 | 165.1 | 165.3 | 164.8 | 0.5 | 4.5 | 6 |

| 178 | 177.8 | 178.1 | 177.5 | 0.6 | 4.5 | 6 |

| 219 | 219.1 | 219.4 | 218.8 | 0.6 | 6 | 6 |

| NOTE: Tubes up to and including 4.5mm wall thickness are subject to a mill rolling tolerance of : + - 0,2 mm. Tubing above 4,5mm wall thickness is subject to a mil rolling tolerance of + - 0.28 mm. All measurements to be taken 150mm from the end of the tube. | ||||||

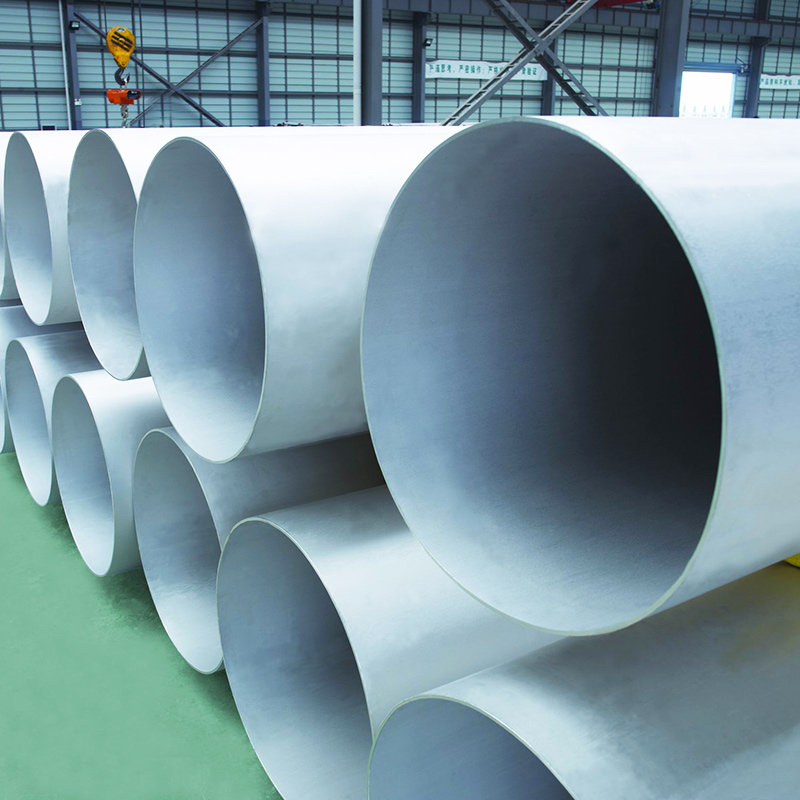

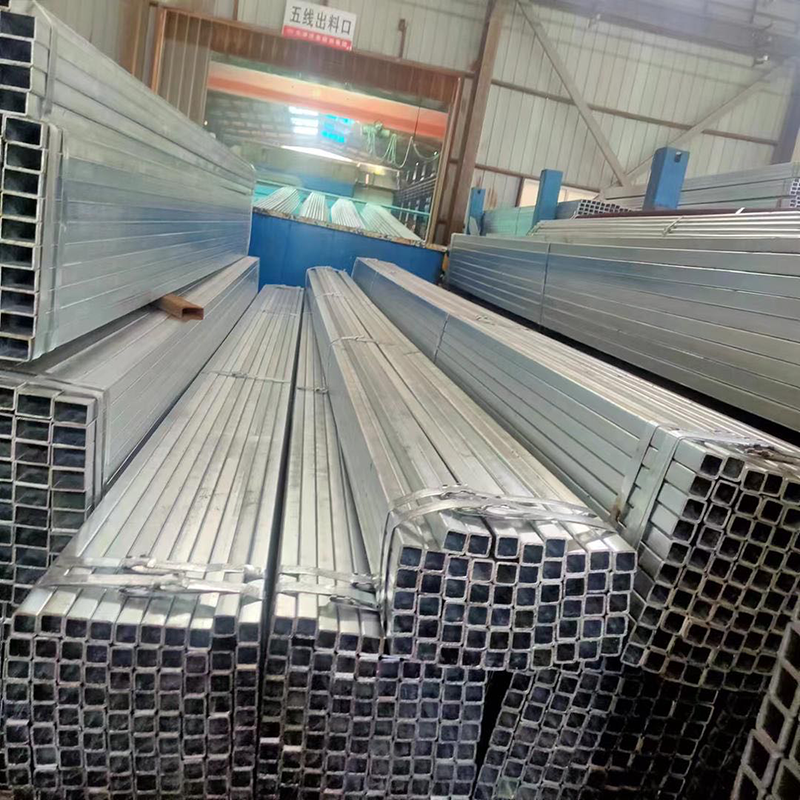

Steel pipes serve as the backbone of modern industrial and civil engineering, supporting a wide array of applications that contribute to the development of societies and economies worldwide. The steel pipes and fittings we Womic Steel produced widely used for petroleum, gas, fuel & water pipeline, offshore /onshore, sea port construction projects & building, dredging, structural Steel, piling and bridge construction projects, also precision steel tubes for conveyor roller production, ect...

Steel pipes serve as the backbone of modern industrial and civil engineering, supporting a wide array of applications that contribute to the development of societies and economies worldwide. The steel pipes and fittings we Womic Steel produced widely used for petroleum, gas, fuel & water pipeline, offshore /onshore, sea port construction projects & building, dredging, structural Steel, piling and bridge construction projects, also precision steel tubes for conveyor roller production, ect...  SANS 657-3, Precision tubes for conveyor roller manufacturing. EN 10305-1, Precision tubes for Heat exchanger and condenser. DIN 2393, Welded precision steel tubes Hydraulic system steel tube BS6323/4, Precision pipes for Electric industry, NF A 49-310, NF A 49-312, Precision pipes for Construction machinery UNI 7945, Seamless precision steel tubes. Steel grade. Fe 280 STN/ČSN 42 6711, Precision seamless steel tubes STN/ČSN 42 6712, Precision seamless steel tubes PN-H 74240, PN-H 74220 Russian Standard Precision Pipes ASTM A450 a A519, Ferritic Alloy / Austentic Alloy Precision Steel Tubes GOST 8734, 9567, 12132 Seamless cold-formed precision steel tubes

SANS 657-3, Precision tubes for conveyor roller manufacturing. EN 10305-1, Precision tubes for Heat exchanger and condenser. DIN 2393, Welded precision steel tubes Hydraulic system steel tube BS6323/4, Precision pipes for Electric industry, NF A 49-310, NF A 49-312, Precision pipes for Construction machinery UNI 7945, Seamless precision steel tubes. Steel grade. Fe 280 STN/ČSN 42 6711, Precision seamless steel tubes STN/ČSN 42 6712, Precision seamless steel tubes PN-H 74240, PN-H 74220 Russian Standard Precision Pipes ASTM A450 a A519, Ferritic Alloy / Austentic Alloy Precision Steel Tubes GOST 8734, 9567, 12132 Seamless cold-formed precision steel tubes

The highly precise steel pipes & tubes we produced widely used for idler roller manufacturer for many years. It's really excited to learn that your company also do well in Idler Roller manufacturer, since we also have many other customers doing the same business as yours. The precise steel pipes produced by us range and tolerance control as below : Regular production diameter: 101.6mm, 108mm, 127mm, 133.1mm, 152.4mm, 158.8mm, 165.1mm, 177.8mm, 219.1mm etc, also customized sizes available. Tolerance control : OD 101.6mm ~ 127mm, On Specified OD Tolerance ±0.1 mm, Ovality 0.2 mm; OD 133.1mm ~ 219.1mm, On Specified OD Tolerance ±0.15mm, Ovality 0.3 mm; On wall Thickness : ±0.2 mm for the pipe wall thickness below and include 4.5mm, ±0.28 mm for the pipe wall thickness above 4.5mm. Straightness : Shall not exceed 1 in 1000 (measured at the midpoint of the tube). Production time is normally 20 days, Looking forward your warm reply and inquiries, thank you

The highly precise steel pipes & tubes we produced widely used for idler roller manufacturer for many years. It's really excited to learn that your company also do well in Idler Roller manufacturer, since we also have many other customers doing the same business as yours. The precise steel pipes produced by us range and tolerance control as below : Regular production diameter: 101.6mm, 108mm, 127mm, 133.1mm, 152.4mm, 158.8mm, 165.1mm, 177.8mm, 219.1mm etc, also customized sizes available. Tolerance control : OD 101.6mm ~ 127mm, On Specified OD Tolerance ±0.1 mm, Ovality 0.2 mm; OD 133.1mm ~ 219.1mm, On Specified OD Tolerance ±0.15mm, Ovality 0.3 mm; On wall Thickness : ±0.2 mm for the pipe wall thickness below and include 4.5mm, ±0.28 mm for the pipe wall thickness above 4.5mm. Straightness : Shall not exceed 1 in 1000 (measured at the midpoint of the tube). Production time is normally 20 days, Looking forward your warm reply and inquiries, thank you